Lean principles in business have had a significant impact for our team. APPRO and CERRON have long respected our manufacturing clients and their processes that lead to quality and efficiency. For this reason, we adopted a Lean Model tailored for us as a service organization.

In this article, you will learn:

- The definition of Lean

- Five Lean Principles

- One Example of our Lean Success

- Links to helpful Resources

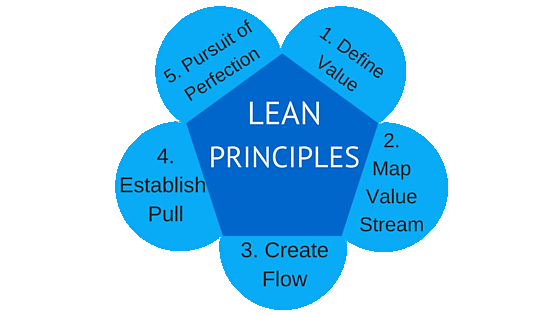

Lean principles are at the core of how APPRO and CERRON work together to streamline processes, while keeping our customers’ best interests paramount in all we do. According to the Lean Enterprise Institute, “The core idea [of lean] is to maximize customer value while minimizing waste. Simply, lean means creating more value for customers with fewer resources.”

Here is one example of our successful use of the Lean process:

Lean Example #1 – Competitive Bidding

Challenge: In order for our clients to make an informed decision regarding a new commercial construction project, they need to have facts and figures in a timely manner.

Solution: Our team created a streamlined bid process, in which we efficiently turn around an accurate, competitive bid request in less time. We created a standardized bid sheet and proposal format. Additionally, we created a list of pre-screened vendors and subcontractors, who comply with our strict safety compliance and insurance requirements.

Benefit to our Customer: The benefit to our client is that we provide a precise bid in shorter time.

{{cta(’20ac84b9-eae3-4e49-8f9d-017ec399ac48′)}}

Our team has has summarized our experience utilizing the Lean principles. We have published a page to our website which includes two examples of the impact Lean has made for our design-build and brokerage businesses.

This full summary, including examples and links to additional resources, may be found on our Lean Principles page:

If you are interested in additional helpful resources for your business, you might find the following pages helpful:

{{cta(‘d7dfe876-5d8f-459f-88d9-69bf94f31a1c’)}}