LEAN MANUFACTURING TOOLS – A QUICK SUMMARY

Our team recently came across an article that is really more of an infographic on the topic of Lean Manufacturing Tools. It is an excellent resource and tool to explain some of the essential Lean tools which can be used in manufacturing. The name of the article is, “32 Essential Lean Manufacturing Tools”and although it was published a couple of years ago, its relevance continues to hold true. As a “manufacturer” of new buildings (and building additions or remodels), we understand the necessity of having a streamlined process, and use many Lean tools. Our team selected our “Favorite Five” from the list and would like to share some of the reasons these are our favorites and how we utilize these tools with our business.

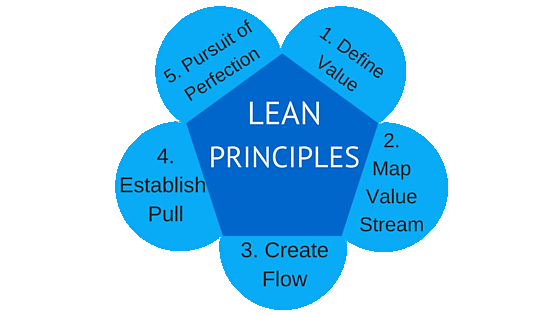

Before we dig into our “Favorite Five”, we wanted to offer a quick summary of Lean, for those of our readers who would like to learn about the basics. According to the Lean Enterprise Institute, “The core idea [of lean] is to maximize customer value while minimizing waste. Simply, lean means creating more value for customers with fewer resources.”

Per the Lean Enterprise Institute, “Lean applies in every business and every process…A lean organization understands customer value and focuses its key processes to continuously increase it. The ultimate goal is to provide perfect value to the customer through a perfect value creation process that has zero waste.”

You may visit our Lean Principles page for more information on the basics of Lean.

Top Five Lean Manufacturing Tools List:

As previously mentioned, this article published by New Castle Systems, summarized 32 tools – that is a lot of tools for your Lean toolbox! We have simply selected our favorite five tools from that list in order to share some highlights on how we have incorporated them into our property solutions business.

1. Continuous Flow – Less wait time, less waste, more efficiency

Our combined APPRO and CERRON team, works to create an efficient process to help business owners achieve their goal of finding a property solution (build a new building, lease a retail space, purchase a new building, add onto an existing building, etc.) with clear and concise communication. While working with a single source, utilizing a streamlined plan, the chance for error or miscommunication is diminished.

2. Kaizen – “Combines the collective talents of the company … to eliminate waste”

On an annual basis, our team identifies opportunities to improve our processes, and we engage in a collective “Kaizen” event. As we work together, we share opportunities to combine our different knowledge, skills and abilities, to benefit each of our clients in our overall process of providing the ideal commercial or industrial property solution.

One example of an outcome of a Kaizen event for our team was our Safety protocol. Working together, we created our standards for a safe work environment in the commercial new construction environment. You may visit our website HERE to learn more about the outcome of this project and our team’s commitment to safety practices in the field of commercial building and construction.

3. Mind Maps – Visual tools to organize and present interrelated ideas

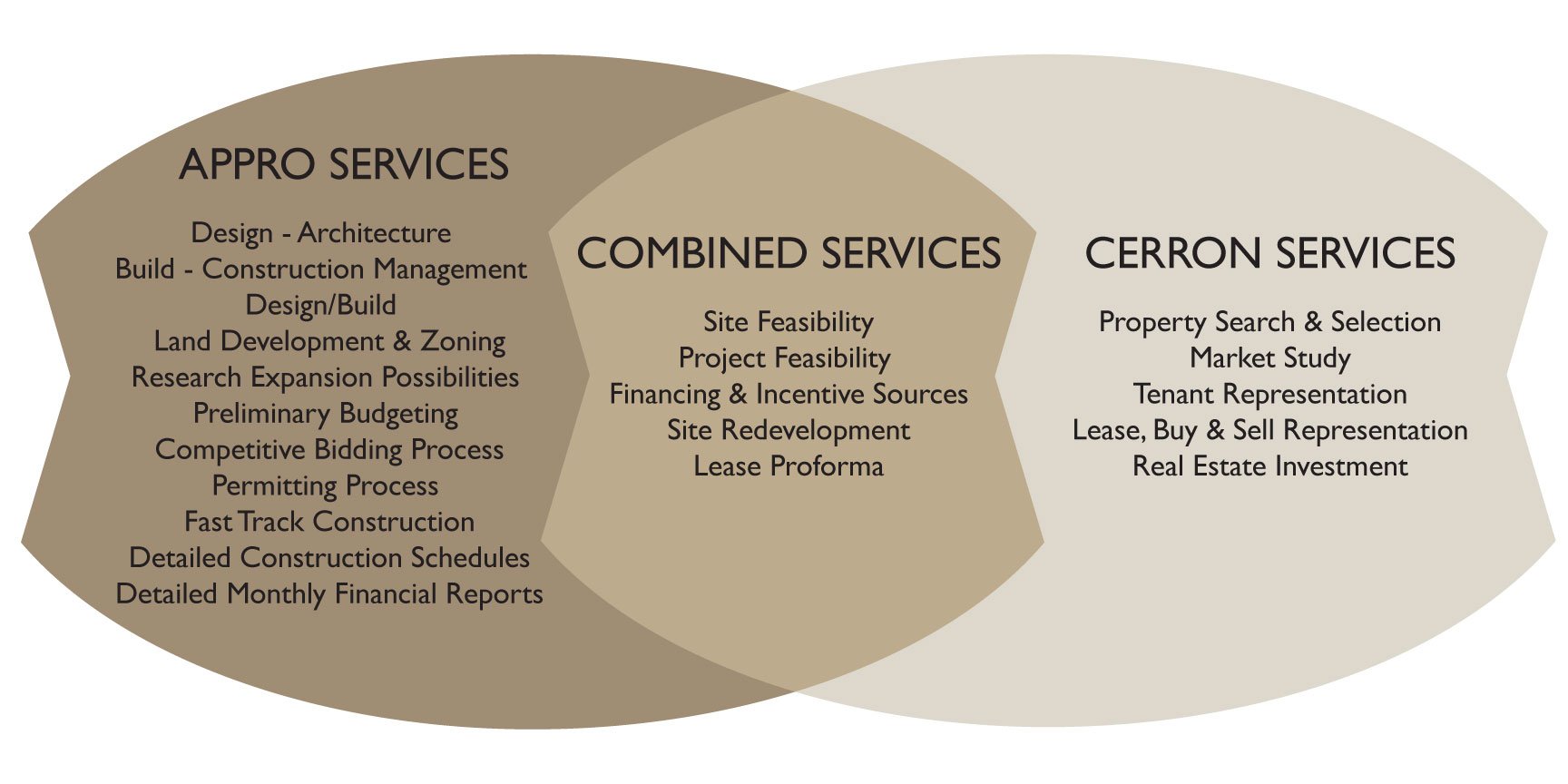

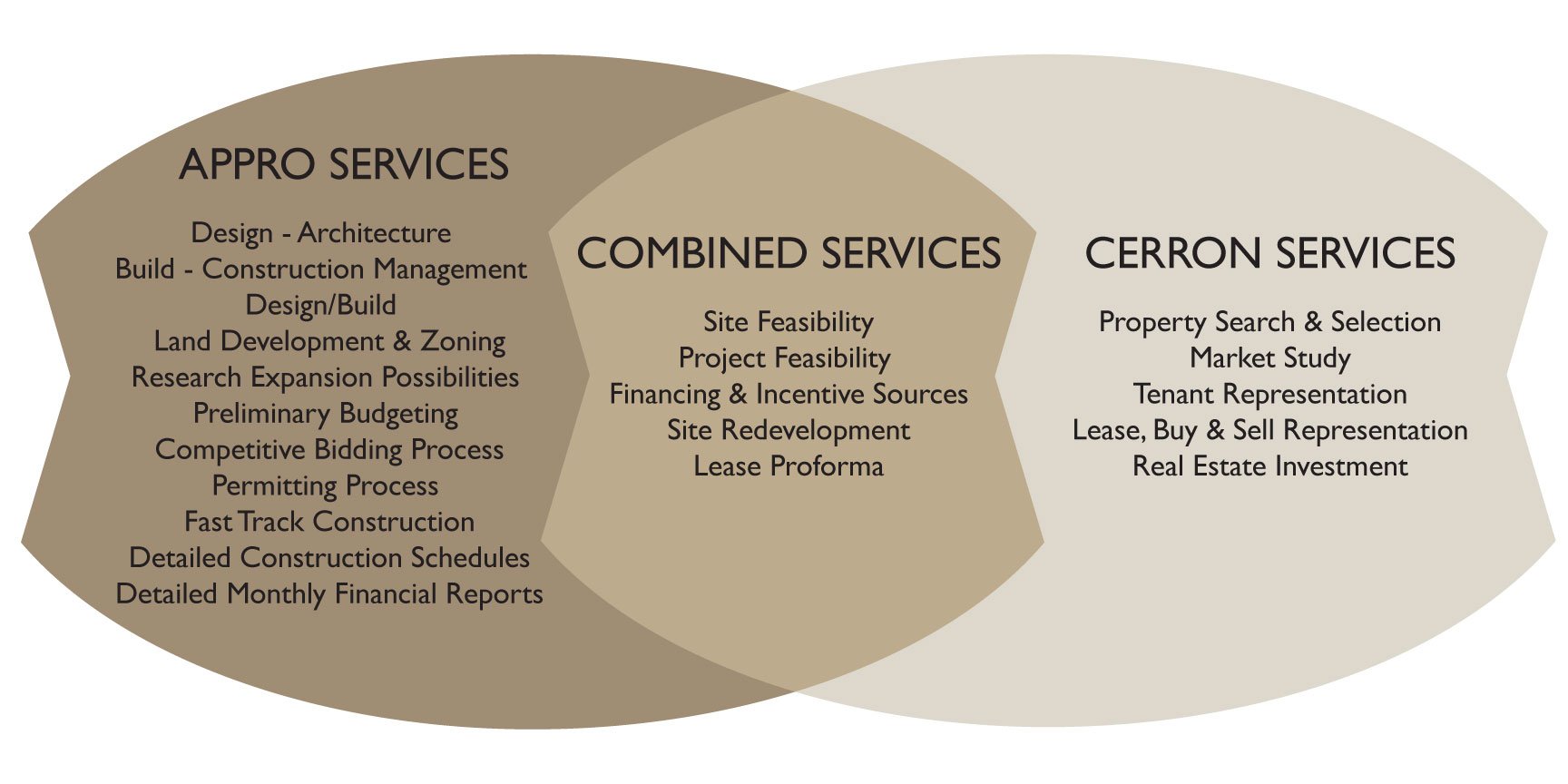

Having the opportunity to share our ideas visually can make a difference. At a time when we were working with a local marketing company to design our logos, we saw that many of the services we provide to our customers, overlapped. As a result, the following graphic was created and used to illustrate the services that both of our companies may become involved and provide services to our clients.

4. SMART Goals – Goals that are Specific, Measurable, Attainable, Relevant, and Time-Specific

Our team works to set annual goals, which we then work toward throughout the year, and revisit on a regular basis to measure the successful attainment of each goal. By having each of the aspects for which “SMART” is an acronym incorporated into the stated goal, the likelihood of achieving the goal increases exponentially.

According to a recent article written by Emily Esposito, titled, “The Essential Guide to Writing S.M.A.R.T. Goals” and published at SmartSheet, they have provided an excellent article on S.M.A.R.T. goals. You will want to consider the following when writing out your goals (the following section is directly from the previously referenced article – with minimal re-wording; the full article may be linked to by clicking on the article title above):

SPECIFIC – When setting a goal, be specific about what you are trying to achieve. In this step – you are going to answer the “W” questions, as summarized in the SMARTSHEET article:

- Who – Consider who needs to be involved to achieve the goal (this is especially important when you’re working on a group project).

- What – Think about exactly what you are trying to accomplish and don’t be afraid to get very detailed.

- When – You’ll get more specific about this question under the “time-bound” section of defining S.M.A.R.T. goals, but you should at least set a time frame.

- Where – This question may not always apply, especially if you’re setting personal goals, but if there’s a location or relevant event, identify it here.

- Which – Determine any related obstacles or requirements. This question can be beneficial in deciding if your goal is realistic. For example, if the goal is to open a baking business, but you’ve never baked anything before, that might be an issue. As a result, you may refine the specifics of the goal to be “Learn how to bake in order to open a baking business.”

- Why – What is the reason for the goal? When it comes to using this method for employees, the answer will likely be along the lines of company advancement or career development.

MEASURABLE – What metrics are you going to use to determine if you meet the goal? This makes a goal more tangible because it provides a way to measure progress. If it’s a project that’s going to take a few months to complete, then break it down into bite-sized, manageable chunks (“mini-goals”) to help track your progress along the way.

ATTAINABLE – This focuses on how important a goal is to you and what you can do to make it attainable and may require developing new skills and changing attitudes. The goal is meant to inspire motivation, not discouragement. Think about how to accomplish the goal and if you have the tools/skills needed. If you don’t currently possess those tools/skills, consider what it would take to attain them.

RELEVANT – Relevance refers focusing on something that makes sense with the broader business goals. For example, if the goal is to launch a new product, it should be something that’s in alignment with the overall business objectives. Your team may be able to launch a new consumer product, but if your company is a B2B that is not expanding into the consumer market, then the goal wouldn’t be relevant.

TIME-SPECIFIC/TIME – Anyone can set goals, but if it lacks realistic timing, chances are you’re not going to succeed. Providing a target date for deliverables is imperative. Ask specific questions about the goal deadline and what can be accomplished within that time period. If the goal will take three months to complete, it’s useful to define what should be achieved half-way through the process. Providing time constraints also creates a sense of urgency.

5. Value Stream Mapping

Provides a road map for improvement through the future state. Our team has used Value Stream Mapping to create a road map for our entire construction process – from site selection to purchase, and from design through the completion of construction. If you have an interest in seeing our construction timeline, you may request a link here:

{{cta(‘5172dd66-1caa-42ac-8d26-0ac15600f407’)}}

This is a visual demonstration of our process and ties into the first tool listed above.

NEXT STEPS:

Take a look at our Lean Page to learn more about how our team uses the Lean process and …

If you are in search of lean manufacturing construction companies, we encourage you to consider our team. We understand the principles of Lean Manufacturing and apply them to our construction process. Meeting with our team to discuss how your manufacturing business is running is a great first step. Simply click on the button below, fill out the form, and a member of our team will follow up. It’s that simple! Thank you for your consideration.

{{cta(‘a783137d-3d9e-4401-98fb-1695e85a9889’)}}

Gear Image Source: freepik.com

SMART Goal Worksheet: